Detail

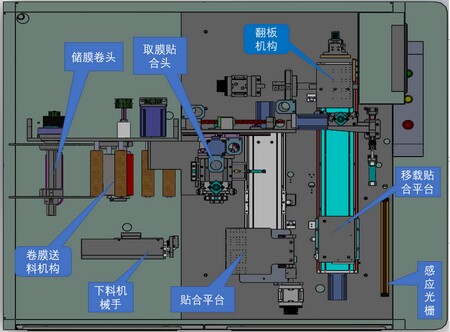

G+F automatic placement machine is suitable for the lamination of soft to hard (Film to Glass) under 1.3-7 inches. The equipment adopts a unique design concept to manually separate the release film and the functional film (Film), and simultaneously adsorb on The cover glass (Glass) on the vacuum platform automatically enters the bonding station, and the film material is accurately and quickly bonded to the substrate. The equipment uses PLC control system and grating induction, the equipment is safe, reliable, highly automated and easy to operate.

Practical application

The equipment is suitable for soft-to-hard lamination under 1.3 inches-7 inches

Film film and cover glass (Glass) bonding

Bonding of TP and PET protective film

Equipment workflow

1. G+F fit

Manually put the film on the turning platform; the correction structure corrects the film. Press the vacuum button, then press the flip to start after the vacuum suction tears the film;

In automatic mode, the operator places the product on the lower vacuum platform, and the sensor starts vacuum adsorption; the operator leaves the sensing area of the vacuum platform, the equipment automatically starts, and the film and the cover are attached.

2. Automatic laminating

The membrane flap structure flips the product front and back, and the mechanical structure runs synchronously;

After the upper indenter sucks the diaphragm, the correction structure automatically corrects the diaphragm, and the upper indenter moves to the laminating station;

The lower vacuum platform runs to the bonding station to complete the bonding;

After the lamination is completed, the upper pressure head will leave and take the film;

The lower vacuum platform runs to the unloading position, the manipulator automatically unloads the material, and the operator repeats the feeding to the turning platform to tear the film and flip; to the vacuum platform, it automatically absorbs and completes the fitting beat.

Equipment efficiency

Overall bonding time: 4 -6 seconds/PCS (depending on the product process)

Equipment capacity: 600-900PCS/hour (depending on the product process)

Debugging time: 30-50 minutes for new product debugging, 1-5 minutes for products with data saved

Advisory