Features of automatic cup mask machine

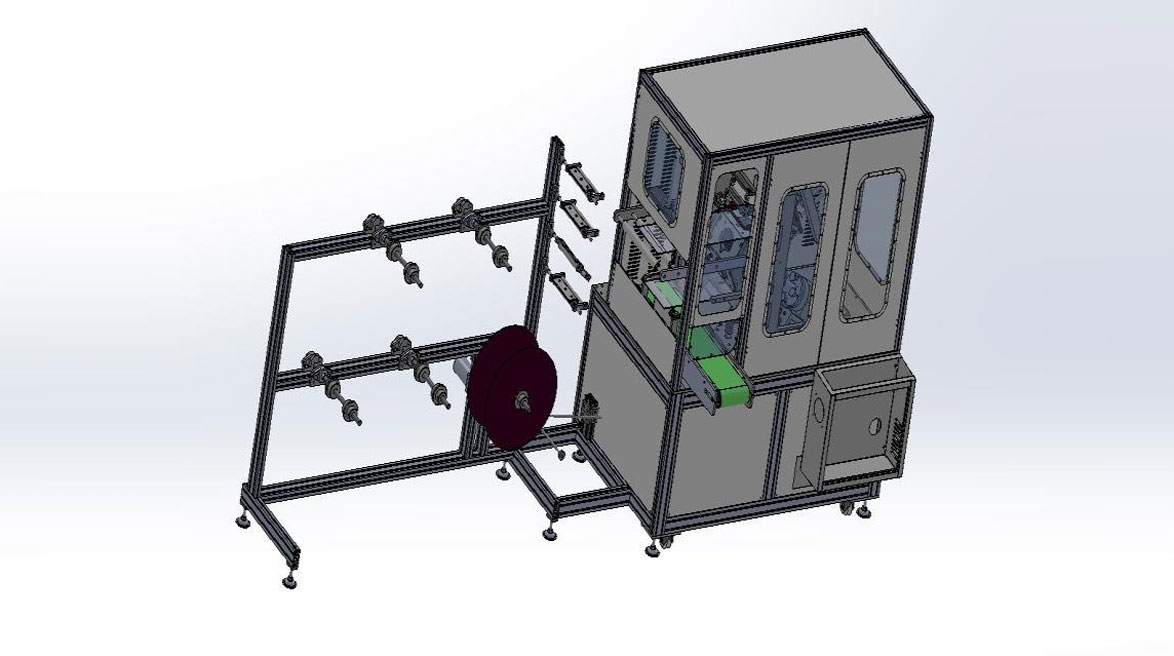

1. The adopted advanced servo and constant temperature control system is controlled by PLC program so that the material enters → forming → welding → punching is completed in one time, and the entire production process is fully automated.

2. The equipment only needs to be equipped with a fully automatic cup-shaped mask nose bridge strip and ear-band welding machine to produce countless cup-shaped mask products that are sold in the market.

3. The fully automatic N95 mask machine represents a new achievement in the industry. The equipment has a high degree of automation. One person can control multiple devices. It can innovate the traditional and complex mask production process to achieve the shape, welding, and punching of raw materials. Completed in turn, all masks produced by its equipment can meet strict European and American testing standards.

4. This machine is a highly automated model developed specifically for cup-shaped masks used in high-pollution industries. The body of the mask can use 1-6 layers of PP non-woven fabric and filter materials. From multi-layer raw materials, automatic feeding and thermoforming, punching the shape of the mask cup, and positioning of the cup. The protective properties of the material will not be damaged during the working process of the machine, and the filtering effect of the finished product can reach the N95 standard.

Parameters of automatic cup mask machine:

Power: 7Kw

Voltage: 220v

Weight: 850kg

Appearance size 3500 x 1500 x 1800mm

Efficiency: 20-30/pcs

Air pressure: 7kg/c ㎡

2. Fully automatic cup mask rear-end integrated machine

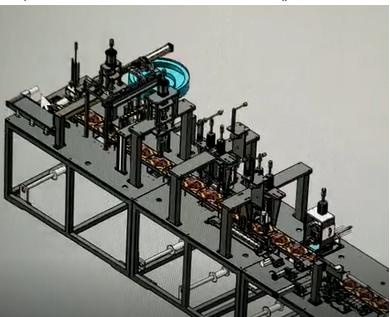

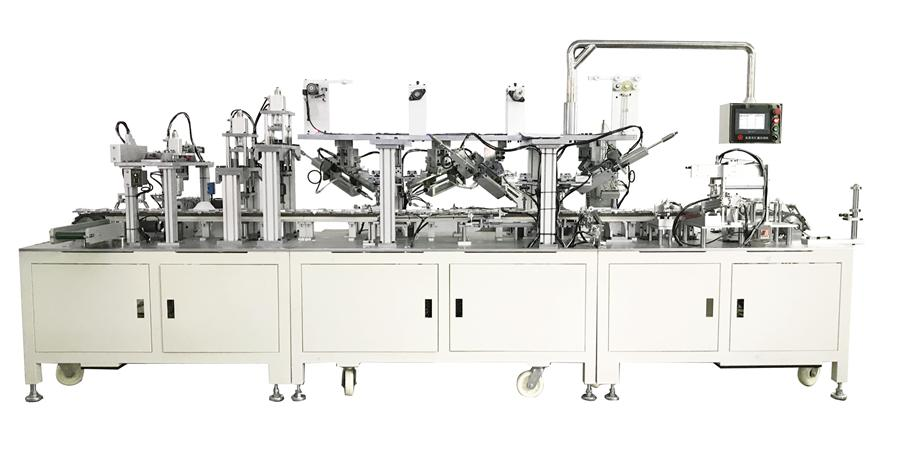

Features of automatic cup mask rear-end integrated machine:

1. Adopt PLC program control.

2. Automatic collection of finished products, precise positioning and convenient operation.

3. The frame structure is made of aluminum alloy, which is not rusty, durable, easy to clean and beautiful.

4. The finished product is firmly bonded and welded beautifully

This machine has a high degree of automation. It uses ultrasonic welding technology and PLC program to work together. Only one person is required to place the mask body on the mold. The follow-up work is from nose bridge welding, breathing valve welding, ear band welding, logo printing to the finished product. The equipment is done automatically.

Parameters of automatic cup mask:

Power: 7Kw

Voltage: 220v

Weight: 900kg

Appearance size 5100(L)*1600(W)*1900(H)

Efficiency: 20-25/pcs